Choose a company

Cerex AG

Specialists in the processing of raw grain products into modern breakfast cereals.

Cerex Industries

Custom work in high-precision mechanical engineering.

CEREX AG · Flugplatz 8 · 3368 Bleienbach · Phone: +41 31 511 34 00 · info@cerex.ch

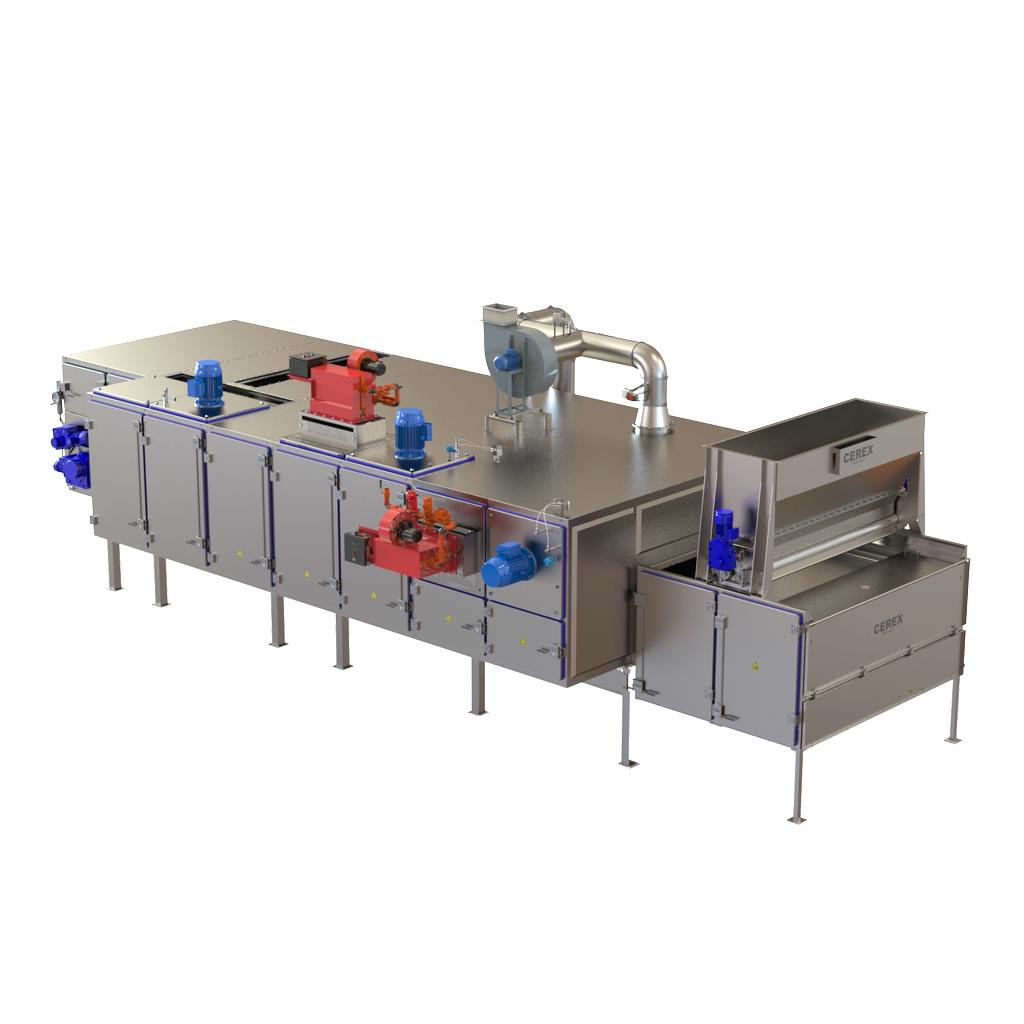

Modern, modular, easy to clean, and based on a reliable process. The CEREX granola dryer offers numerous benefits in comparison to the existing machines.

Options: