Choose a company

Cerex AG

Specialists in the processing of raw grain products into modern breakfast cereals.

Cerex Industries

Custom work in high-precision mechanical engineering.

CEREX AG · Flugplatz 8 · 3368 Bleienbach · Phone: +41 31 511 34 00 · info@cerex.ch

CEREX is working in association with the A.T. Ferrell Company in the USA.

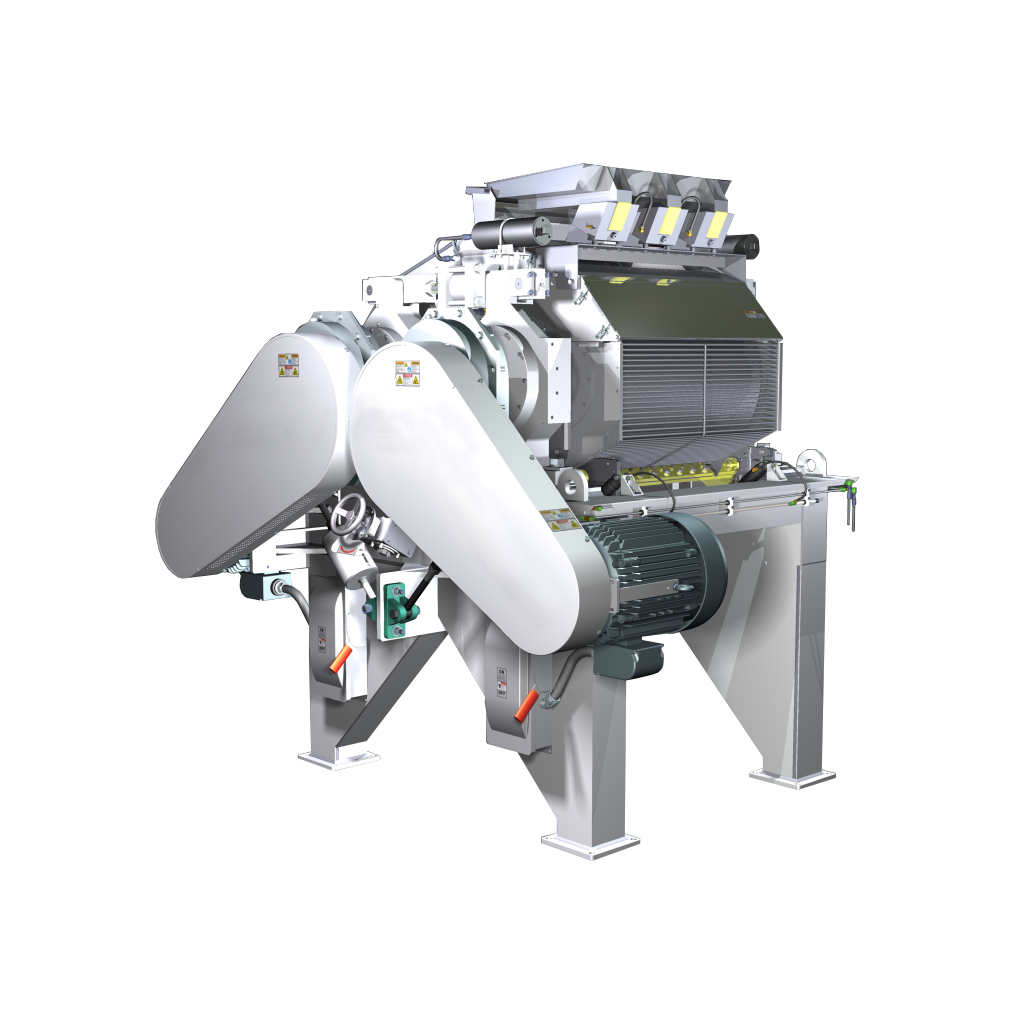

The Ferrell-Ross Flakers are designed by A.T. Ferrell and assembled by CEREX in Switzerland.

The Flaker is designed for complete cereal processes such as cornflakes or multiflakes.